2465Views

Damen FCS demonstrates versatility again in collaborative technology project

Delft Dynamics, Next Ocean and Damen perform qualification test in North Sea

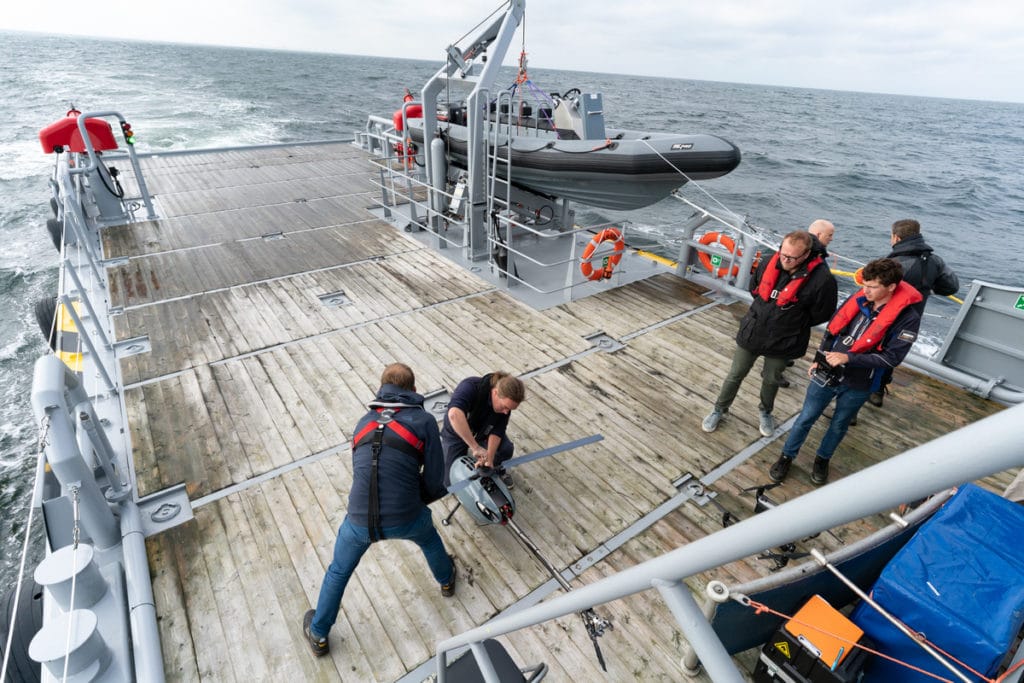

Damen Shipyards Group, in collaboration with Delft Dynamics and Next Ocean, has trialled a new approach to search and rescue in the North Sea. The collaboration involved qualification testing of Delft Dynamics RH3 drone (RH-3 Swift), along with a fast rescue boat launched from a Damen Sea Axe Fast Crew Supply (FCS) Vessel equipped with Next Ocean’s wave and vessel motion predictor.

The goal was to test the limits of drone helicopter operations offshore; a significant project given the notable size of the drone involved. The test was funded by the Dutch Ministry of Defence and support by the Royal Netherlands Navy and the Netherlands Coastguard.

Delft Dynamics is currently working on the next stage in the evolution of its unmanned helicopters, a drone with the capability to carry out observation for durations up to four hours. A logical environment for such capabilities is offshore. Hearing the company’s feasibility study presentation regarding launching such a vehicle from a vessel, Damen came on board the project with the suggestion of adding a fast rescue boat to the process.

The partners foresaw that the most challenging part of the project would be launching and landing the drone and boat in rough seas. At this point Damen called upon the expertise of Next Ocean – the producer of a wave and vessel motion predictor, which Damen had already experienced in tests on one of its Stan Patrol ships.

The wave prediction system uses the ship’s radar to map the sea approximately 1 nautical mile around the vessel, enabling the prediction of wave activity accurately for the coming three minutes.

“With this we can predict when there will be a window of opportunity to launch the drone and the rescue craft. Take-off and landing of the drone takes just 30 seconds, for example,” explains Albert Rijkens, Damen High Speed Craft Portfolio Manager R&D. “The wave prediction system makes this approach feasible and safe.”

“Performing this test was a tremendous success and demonstrated clearly the feasibility of taking off and landing the drone in rough seas, especially with the excellent sea-keeping behaviour of the Damen Sea Axe bow, paving the way for its use in a wide variety of offshore operations, including search and rescue, fishery inspection, border patrol and humanitarian aid missions,” says Delft Dynamics’ COO and Co-Founder Boris Langendoen.

The test also provided additional data for the further development of the Next Ocean wave prediction system, states Karel Roozen, Co-Founder of Next Ocean. “The system is in a state of constant evolution. The more data we collect, the more we can improve on its capabilities. The current version is developed for operations on board dynamically positioned or slowly (up to aprox. 8 knots) moving vessels. Apart from demonstrating the system at low speed, we gathered information during this trial which will help prepare it to operate at up to 25 knots or even higher speeds, paving the way for a whole new set of additional applications.”

This cooperative approach is, according to Albert, the key to innovation. “At Damen we hold the philosophy of ‘collaborate to innovate’. It’s something we have done for years already. Working together with our partners – particularly start-ups with the innovative ideas they are looking to trial – is an excellent way to look at ways in which technology can help our clients make their maritime operations safer, more efficient and more sustainable.”

Damen Shipyards Group

Damen Shipyards Group operates 36 shipbuilding and repair yards, employing 12,000 people worldwide. Damen has delivered more than 6,500 vessels in more than 100 countries and delivers around 175 vessels annually to customers worldwide. Based on its unique, standardised ship-design concept Damen is able to guarantee consistent quality.

Damen’s focus on standardisation, modular construction and keeping vessels in stock leads to short delivery times, low ‘total cost of ownership’, high resale values and reliable performance. Furthermore, Damen vessels are based on thorough R&D and proven technology.

Damen offers a wide range of products, including tugs, workboats, naval and patrol vessels, high speed craft, cargo vessels, dredgers, vessels for the offshore industry, ferries, pontoons and superyachts.

For nearly all vessel types Damen offers a broad range of services, including maintenance, spare parts delivery, training and the transfer of (shipbuilding) know-how. Damen also offers a variety of marine components, such as nozzles, rudders, winches, anchors, anchor chains and steel works.

Damen Shiprepair & Conversion (DSC) has a worldwide network of eighteen repair and conversion yards of which twelve are located in North West Europe. Facilities at the yards include more than 50 floating (and covered) drydocks, including the longest, 420 x 80 metres, and the widest, 405 x 90 metres, as well as slopes, ship lifts and indoor halls. Projects range from the smallest simple repairs through Class’ maintenance to complex refits and the complete conversion of large offshore structures. DSC completes around 1,300 repair and maintenance jobs annually, both at yards as well as in ports and during voyage.

IMPORTANT

This Press Release was requested for publishing by an external entity not associated with Quwa. Comments, opinions and discussions by external entities are not those of Quwa. Thus, Quwa does not accept responsibility or liability for the content of this Press Release. Quwa does not grant rights to reproduce or use this content. If your company would like to request Quwa to publish a press release, please contact us (link).