2449Views 6Comments

India media report of successful ATAGS howitzer firing tests

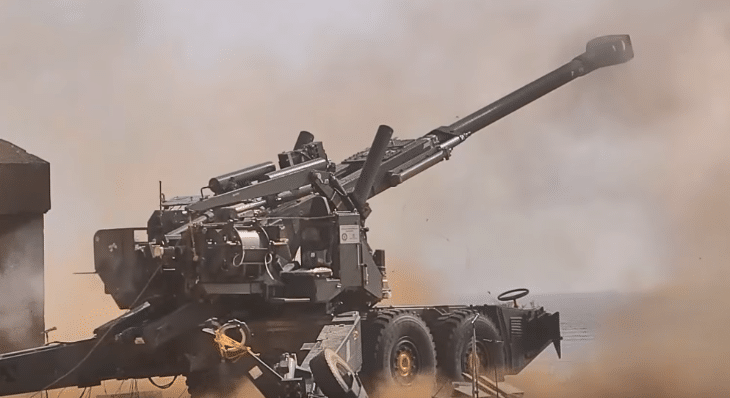

The Business Standard reports that the Advanced Towed Artillery Gun System (ATAGS), a dual-track joint-program between the Defence Research & Defence Organization (DRDO) and (in parallel) Tata Power and Bharat Forge, yielded “world-beating” records from its firing tests in Pokhran, Rajasthan.

The ATAGS howitzer that was recently tested was the one developed by DRDO and Tata Power’s Strategic Engineering Division. It is a 155 mm and 52-caliber howitzer. The ATAGS reportedly fired three shells to a range of 47.2 km using a high-explosive base-bleed shell.

Comparable howitzer guns firing base bleed shells generally have maximum firing ranges between 40 and 45 km. For example, the Denel Land Systems T5-52 and Yugoimport-SDPR NORA B-52 can fire base bleed shells to 42.5 km and 41 km, respectively.

DRDO reportedly credited the range extension to the ATAGS’ larger chamber (25 litres vs. 23 litres), which affords additional space for high-explosive propellant. However, the ATAGS is also heavier than its foreign analogues, weighing 17,000-18,000 kg in comparison to 14,000 to 15,000 kg.

The ATAGS also benefits from an all-electric drive system for each part of the gun, including the handling of the ammunition, opening/closing the breech, and inserting the round into the chamber for firing. The aim of the system is to reduce maintenance and maintain reliability for long-term usage.

In January, The Hindu reported that the Indian Army was optimistic about the ATAGS, with a senior Indian Army officer telling the newspaper: “The gun has come up very well. The way the project is unfolding, if it continues that way, it will be one of the finest guns in its class in the world.”

The ATAGS is a collaboration between the public and private sector. While DRDO’s Armament Research and Development (ARDE) spearheads the ATAGS’ design, private entities Bharat Forge, Tata Power SED and Mahindra Defence Naval System are involved in the development and production process.

India commissioned the ATAGS’ development in 2012. Production of the ATAGS prototype began in 2014, with tests commencing in July 2016. The aim of the ATAGS was to provide the Indian Army with a domestic artillery platform that is readily at-par with foreign designs.

6 Comments

by Jagdeep Singh

It already made many world records . That particular prototype was of TATA . Next trails would be started at Sikkim anytime soon. It may start serial production in 2018 and mass production in 2019-20.Year 2019 is very important, in same year we would got M77 in large no.s, S400 deliveries, Rafale deliveries, ATAgS, Mark1A full scale production, TejasMark2 prototype, Kaveri engine at aero india, Chinooks,Apachis, super sukoi deal, HAL trainor jet program, New gun platform, MRCA2 tender, INS Vikrant, RafaleMs, ATGMs, New t90ms, Frigates, INS Aridhaman trails, designing of attack submarine, K226 deliveries, LUH serial production, etc etc

by Lasit

this is a very positive development for the Indian defense sector, specially the involvement of the private Indian companies in the development and manufacturing of the Artillery.

India gradually needs to strengthen our private defense sector and create some competition for our Govt agencies, specially the OFB.

by MT

India needs to be ditching public sector esp ordinance factory for manufacturing. R&D and research should remain with govt psu where as design, precision manufacturing should be delegated to private sector companies . I envisage Tata SED building next gen tanks, artillery vehicle in coming decades.

by Jigsaw

Will it be mass produced. Question mark.

by Jack More

ahh was waiting for your expert comment.I think the gun already proved itself by making world record and already ordered by army.

by MT

Military sector manufacturing was a concern due to sloppy govt owned defence sector marred by unaccountable public servants..

But capabilities of Pvt sector giants such as Tata SED, Tata advanced materials, Bharat forge will eventually place India at par with other global peers and companies in precision manufacturing.

Bharat forge is already world’s top 3 forging manufacturing powerhouse. They have tied up with rolls Royce in manufacturing aircraft engine components and parts.

Gradually these companies ll transform indian military ecosystem. They have shown their mark in civilian sector. With billions of funds, capital and capabilities to hire global talent you ll see them deliver as they did with jaguar land rover.